Docking AGV

Docking AGV can be connected with automated assembly lines and conveyor lines to achieve flexible material handling and docking between assembly lines, support multi-type material transportation, such as pallet materials, carton materials, etc., significantly improving the efficiency of workshop logistics.

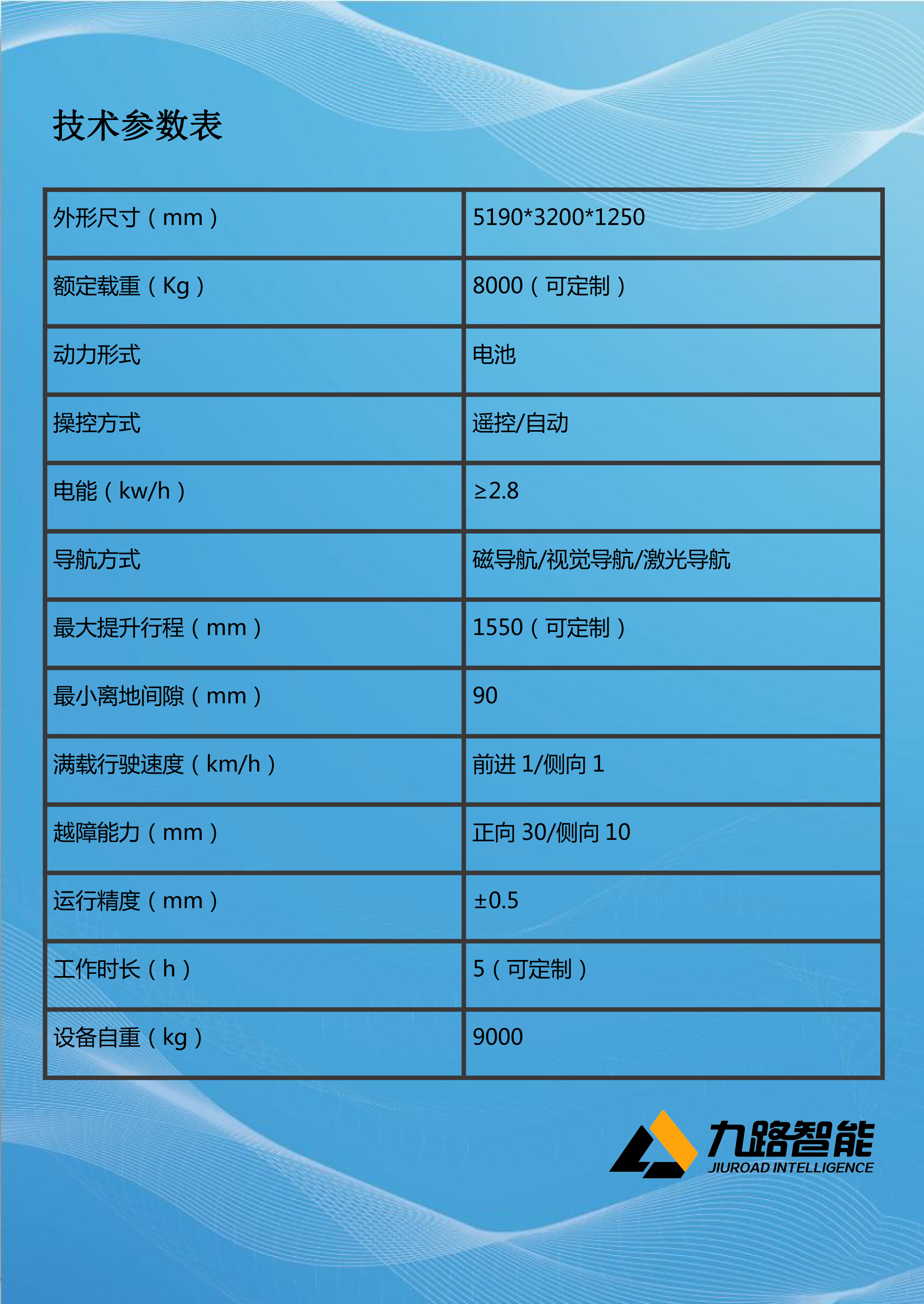

The docking AGV is a two-drive docking AGV, which can pull at least 1000KG of excess cargo, and can advance, retreat, accelerate, decelerate, turn, automatic stop and other two-way driving functions. AGV sheet metal body is sprayed with a beautiful appearance, a strong surface and corrosion resistance. This AGV is a dual-drive docking type, which can automatically walk in both directions along the set route forward and backward, from the raw material warehouse to the production line, from the production line to the finished product warehouse, etc., to complete the automatic feeding and unloading of the production line station, create an unmanned automated production workshop, and maximize the production efficiency of the enterprise.

Applicable scenarios: Suitable for warehousing applications in various manufacturing industries such as shoes and clothing, electronic manufacturing, manufacturing, and medicine.

Related Products

Submitted successfully

We will contact you as soon as possible