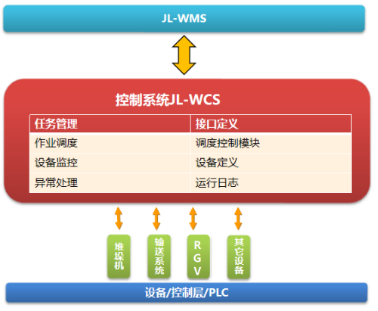

JL-WCS intelligent warehouse control system

Nine-way intelligent warehouse equipment control system WCS, the full name is WareHouse Control System. It is a layer management control system between the nine-way intelligent warehouse management system WMS and the underlying equipment PLC drive system. The main function is task scheduling and equipment operation status monitoring.

1. Task execution and scheduling

The port listening mechanism is used to obtain the task packets issued by the WMS of the warehouse management system in real time, and parse and generate the device layer instructions, select the execution role according to the task content, and then send them to the PLC drive system of the corresponding device.

2. Task tracking and monitoring

After the task is issued, the execution status of the warehouse operation is tracked by reading the PLC instruction execution status in real time, and the data is interpreted as identifiable information and displayed to the front-end UI window.

3. UI model data driven

In ui design, you can use 3D models to display all the information of the warehouse, and WCS provides data-driven for the model to achieve consistency between the UI model and the warehouse reality, and truly achieve the 3D display effect of the warehouse scene.

Information interaction can be supported, that is, the corresponding operation is performed on a device in the UI model, and the instructions are responded to by the WCS.

4. Equipment abnormal monitoring

When the equipment is abnormal, the abnormal information is captured in real time and reported to the WMS system, which supports different levels of alarm mechanisms.

Related Products

Submitted successfully

We will contact you as soon as possible