JL-WMS Intelligent Warehouse Management System

The space planning is more reasonable, which greatly increases the warehouse storage space

The supply chain module is more perfect, and the warehouse information management is more powerful

Pick multiple orders at the same time to improve picking efficiency

Paperless office, real-time synchronization of information

Highly automated, intelligent and efficient work

The WMS system integrates intelligent logistics equipment in the warehouse and becomes the brain that directs and coordinates logistics equipment.

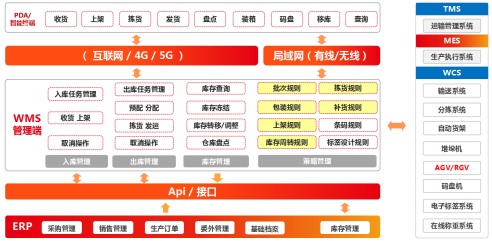

Jiulu Intelligent WMS Warehouse Management System, full name WareHouse Management System, is an important part of the ERP of enterprise resource management system, and the main business modules include warehousing business, outbound business, warehouse transfer, inventory allocation and virtual warehouse management in the material storage business.

Through the batch management, material correspondence, inventory inventory, quality inspection management, virtual warehouse management and real-time inventory management and other functions, the effective control of logistics costs is realized.

The WMS system can operate independently to achieve refined management of the warehouse, and can also establish data sharing with other higher-level systems through standard interfaces.

In the application scenario of automated intelligent three-dimensional warehouse, the WMS system sends warehouse operation tasks to the automated storage equipment for execution through close integration with the WCS system.

Related Products

Submitted successfully

We will contact you as soon as possible