Industrial heavy-duty intelligent warehousing projects

Project Contents: Three-dimensional storage project of finished cloth of a printing and dyeing enterprise in Zhejiang

Warehouse type: intelligent AGV forklift warehouse

Construction scale: 2600 cargo space

Main equipment: intelligent AGV forklift, intelligent AGV handler, supporting nine-way intelligent WMS warehouse management system, WCS warehouse control system.

Project completion time: March 2022

Project features: The warehouse area is planned under the scene of high floors and low floors, and the cloth carriers are very regulated, and the efficiency of entering and leaving the warehouse is high.

The construction of the three-dimensional warehouse of the project will upgrade the storage mode of the original ground floor to three-layer shelf storage, effectively improving the utilization rate of space storage by 300%; The application of AGV automation equipment reduces personnel costs, reduces warehousing operating costs, and improves the efficiency of storage operations.

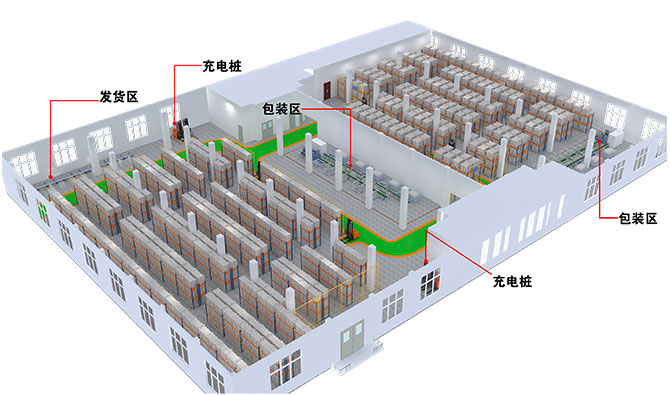

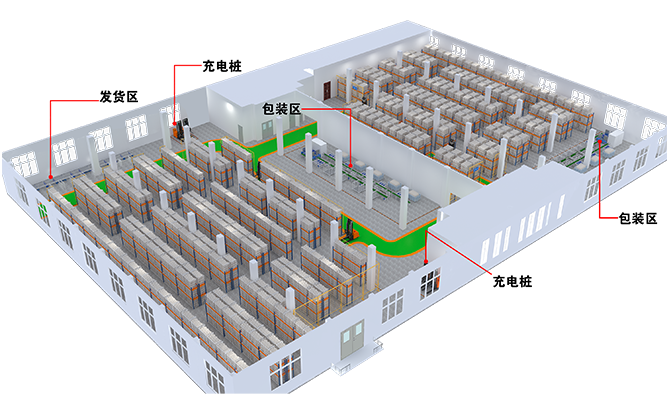

(Aerial view of the cloth warehouse)

(Finished cloth warehouse renderings)

(Finished cloth warehouse renderings)

(Finished cloth warehouse renderings)

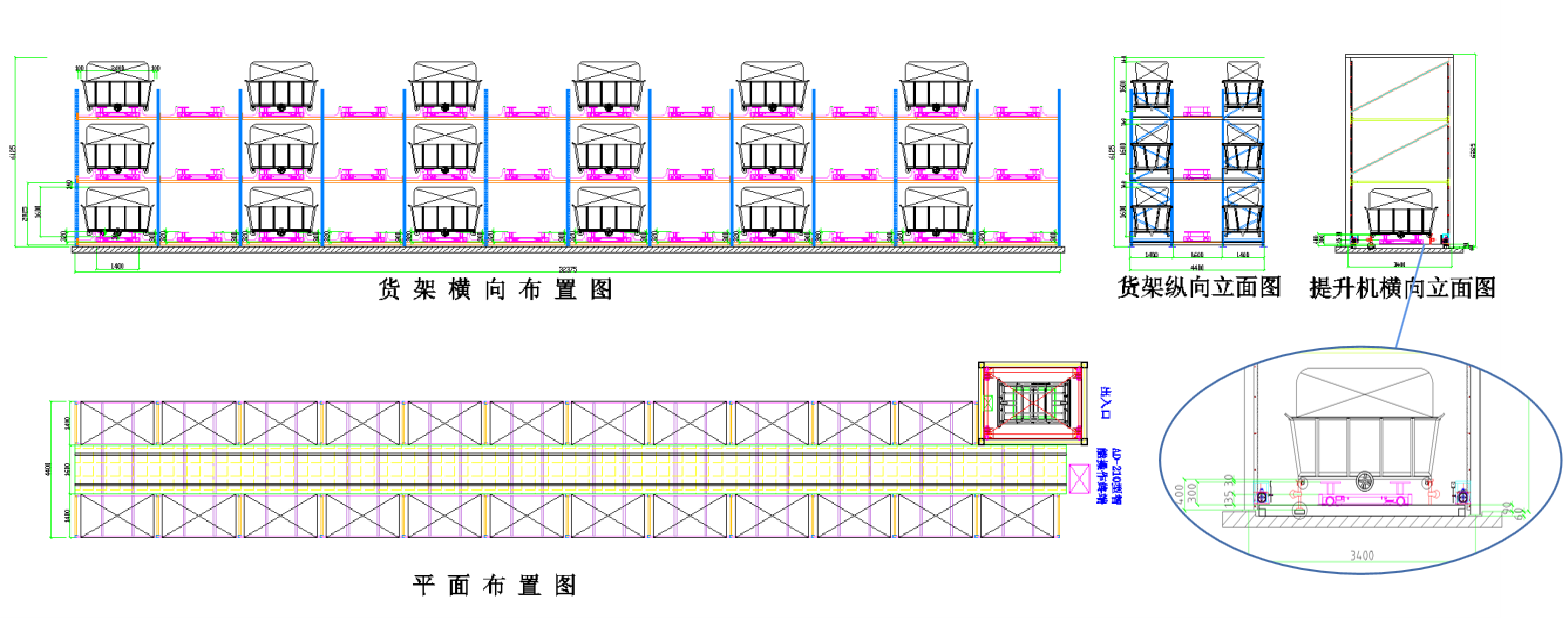

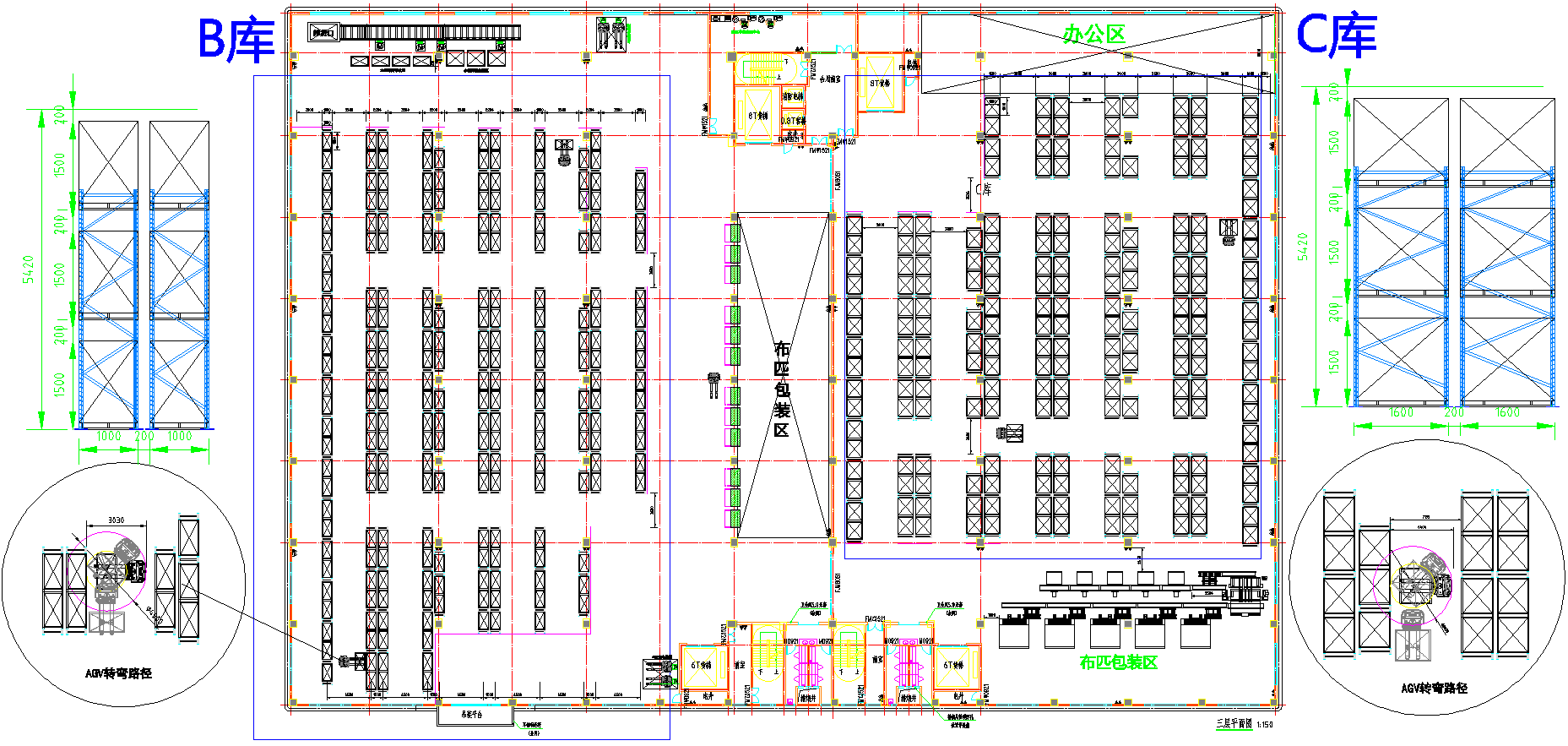

(Layout storage warehouse planning plan)

(Finished cloth warehousing planning floor plan)

Related Products

Submitted successfully

We will contact you as soon as possible