Industrial heavy-duty intelligent warehousing projects

Project Contents: A three-dimensional warehouse for raw material storage of a paint manufacturing enterprise in Zhejiang

Warehouse type: stacker truck warehouse

Construction scale: 1600 cargo space

Main equipment: industrial heavy-duty stacker, RGV rail guidance vehicle, automated conveyor line equipment, supporting nine-way intelligent WMS warehouse management system, WCS warehouse control system.

Project completion time: August 2021

The project plant area of a new three-dimensional warehouse, stacker and high shelf storage in the 1200 square meters of building area, to achieve more than 1600 effective cargo storage space, to achieve the maximum utilization of space storage. Automated input and output equipment, effectively control the input of personnel costs, ensure the efficiency of raw material warehouse throughput, and meet production needs.

(Project construction renderings)

(Project construction renderings)

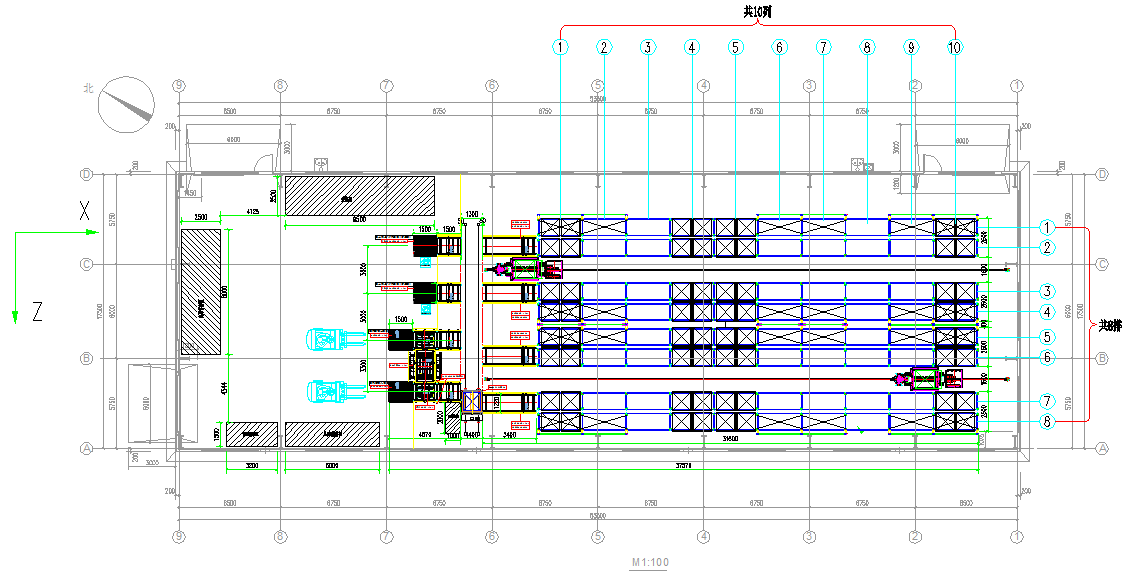

(Project Planning Floor Plan)

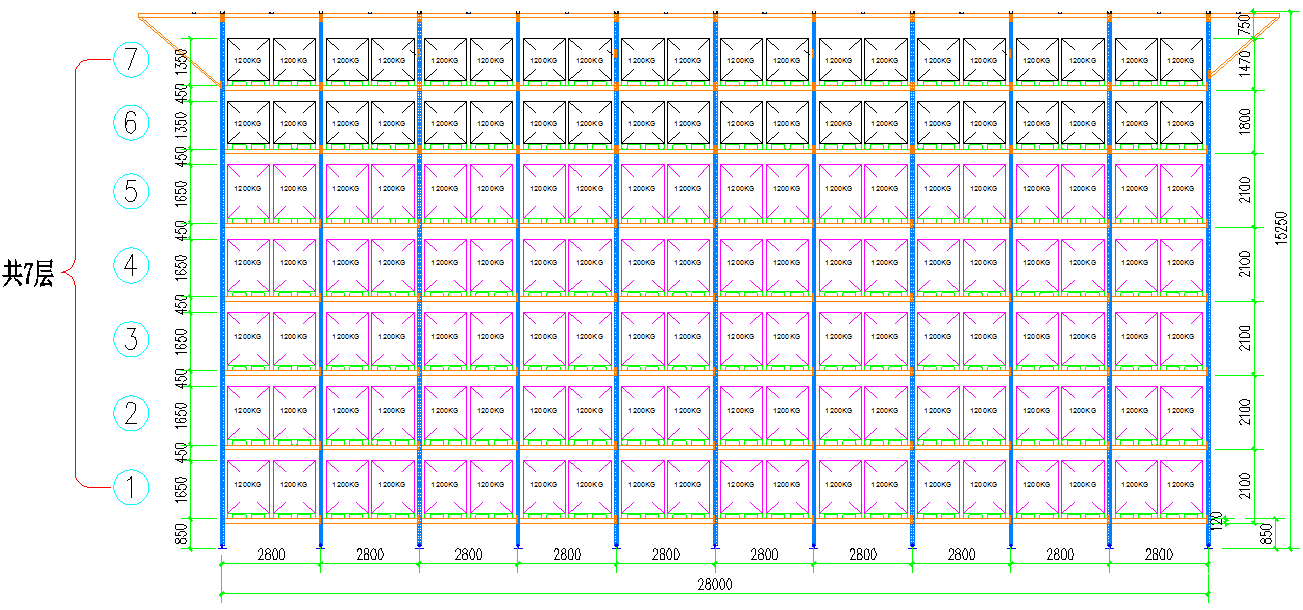

(Project planning layout elevation)

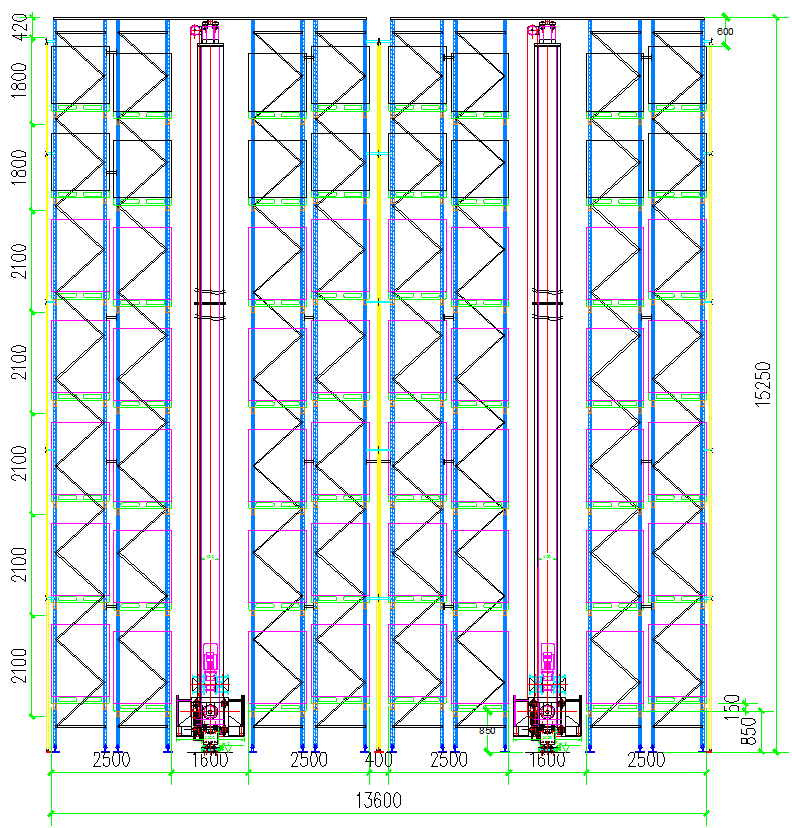

(Project planning layout elevation)

Related Products

Submitted successfully

We will contact you as soon as possible